If the tread depth is within a maximum of 4/32" from side to side then you're fine with just swapping it out. Getting over that number you start to overwork the differential (it constantly works due to different tire diameters) and cause premature parts failure. But if you only have a couple thousand miles on the tire i doubt you've worn much off of them. Soooo go for it.

Posts by Karvor

-

-

I used the probe pushed through the radiator fins on my Trans Am and it worked flawlessly. However on a Jeep that will get jarred around offroad i would i suggest the style that uses the temperature sender on the engine instead. I would also suggest the heavy duty, adjustable variety. That way you can dial in a different temperature for street use and for lower it for when your working the jeep hard offroad. All just suggestions, but it's what i would do if the rig were mine

-

Hey Spedly, does it ride softer with the air bags? The wife is recovering right now from a 3 level cervical fusion and i"m building the jeep for her to wheel with. So breaking stuff isn't too big of a deal to me if it provides a more comfortable setup for her. And since you work on them so much could you point me in a direction to find the bags? Most of them i have looked at only show me compressed height and not extended height nor load capacity.

Thanks for the info there Mr. Knoxrents. Not sure if i'm gonna go that over the top on the system.....The more i play with this project, the further the completion date moves out :o . I'm gonna do some more research on it. And hopefully pick Spedly's brain from time to time on it. -

Been toying around with the idea of useing air bags on the project TJ. For multiple reasons actually. 1) I'm going to fab up my own long arm system for it and was thinking it would be nice to be able to air the bags all the way down to make it easier for the wife to get in and out. 2) If i set up a per axle manifold for the pair of springs, as one wheel gets tucked up into the wheel well it would force air to the other side bag and place more downward pressure on the side with less weight. 3) I could dial up different lift heights by air pressure regulation for different situations.

Now i have zero experience with a set-up like this, and my thoughts are experimental type ideas. Anyone have any experience with air suspension and it's limitations? -

Count me in. We could do more than 1 location, lower for the southies and upper for the northies. Makes little difference to me ;D . I also drive a Dodge Ram so we can fit quite a bit in the bed even though it's only a 6 footer.

-

I've heard good things about Firestone Destination A/Ts, and I have Toyo OpenCountry A/Ts on my WJ at the moment. Only issues are the rain sometimes, but that's any tire with a RWD. Tire noise is audible when no music is playing, but I don't mind it

If you need help, I'm in Newark every day for work and basically every weekend.

I have the Firestone Destination A/T's on my Dodge Ram and the tread pattern is so mild i would call it more a street tire than an all terrain tire. I think it's the heavier sidewall and whatnot that classifies it as A/T. -

Quote

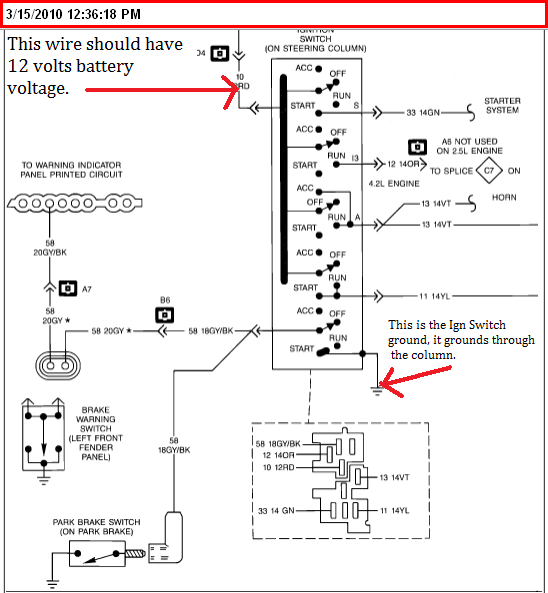

I am only getting 5v's on the red wire in the black conn and none of the others. This is a brand new Ign switch. Should I be getting a full 12v's to the ign switch? Like I said, I have 12v's all the way up to the bulkhead connector now but only 5v at the connector for the Ign switch. Is that normal or am I looking at tearing the dash and fuse block apart?

Definately losing juice there. With the bulkhead connector installed, check for voltage at the red wire at the bulkhead connector inside the Jeep. i.e. not the engine compartment side. If you get 12 volts there, the easiest method to fix is to cut the red wire a couple inches back from the bulkhead (inside the jeep) and do the same at the ignition switch and solder in a new wire. -

Ok i found the wiring diagram for the ignition switch. Do you remember what color the fusible link was that you replaced? From the diagram i am not seeing where a 5 volt reference would be going into the ignition switch. Where were you testing the voltage at? Here is a slightly modified diagram for you:

The switch grounds through the column, so if your column connections are corroded or your body grounds are poor this can give you a problem. You can rule this out by temporarily adding a ground to the column. Try running 1 lead of a set of jumper cables from the ground on the battery to a clean metal point on the column. In the event this does remedy the issue, try taking the jumper cable off the column and attach it to a point on the body, like maybe where the door strap attaches. If it still works you have a bad body ground. Let me know what readings you get at what terminals on the ignition switch. -

Once i get home and fix the internet and check the sump i'll take another look at the diagram and see whats what.

-

Yes Jeep did use a duct tape looking stuff over their factory splices, but what bothers me is the cut wires i see to the right of the splices in the first pic.

-

How long until it fades? Is all that work worth it to you if it's only 5 years?

For me, i'm going to be doing 'something' anyhow. The Jeep will be a trail rig almost exclusively so i won't have to worry about scratches. I guess only time will tell how well the color holds up, gonna be going with a dark blue. -

Once i get done with the frame on my TJ i will be moving on to the tub and fixing the rotted body mount points. Then i will doing the liner portion of the job. So depending on how quickly you plan on doing yours....I will have a whole series of pics up in another month or so on that part of it.

-

I plan on doing the entire Jeep with bedliner, thinned down so it's not the ugly course surface and w/o the rubber chucks in it. There is a guy that is very active on one of the Jeep forums (don't remember which offhand) that is a supplier. His customer service is excellant, and you tell him what you want the end product to be / look like and he'll run some test patches at his business to help you figure out exactly how much to reduce the mixture, and it is tintable.

http://monstaliner.com/

The website also has quite a few pictures and 'how to' videos. It's where i will be getting my kits from. -

Thanks guys, I tore the 4.0 down and found it had the 4.0 head curse. Valve guides are worn beyond spec, all valve seats are worn down lopsided so none of the valves actually seat like they should on the intake side

. More expenses to add to the list for the project Jeep.

. More expenses to add to the list for the project Jeep. -

I don't suppose anyone here owns or works for a machine shop. I'm in need of some work on my 4.0

-

I have access to the Starscan, the problem is going to be in getting the proper update for it. The Starscan looks for the ECM part number, and depending on the brand of tuner, it changes the part number. And i would have to download the update for it from work if it isn't saved in the tool, I suppose we could hook it up and see what comes of it from there.

-

Since this is a Jeep club, and technically our business name IS still Hertrich Nissan Jeep AMC, I Just stated it as HNJ. I'm not sure when it was that you had your bad experience, or who it was you dealt with but it sure doesn't sound like our current service manager. And to say not to count on anything from them when i work there, am a member here, and would do anything I can to help out anyone here. Including grabbing the factory scantools from work and checking out any problem for you guys outside of the shop after hours. The only thing I can't use is Tech connect :upset: . Sorry for hijacking the thread, and sorry if i took statements a little more personally than they were meant to be said.

-

Not to mention a dealer will not know you have regeared unless you have a differential issue.

When i did driveline work on any Jeep (I'm a tech at Hertrich Nissan Jeep) I noted all pertinant driveline info on every work order including the differential gear ratio. All you need to do is count how many turn of the driveshaft it takes to get 1 full turn of the wheel. But at Hertrich when we had the Jeep franchise we didn't care about what mods were done because we saw it as work in the shop that wouldn't be there otherwise. However other dealers would not touch a Jeep that had mods, Holden was one of them, not sure what their policy is now but they used to send them all to us. -

Just something to think about, if the gears you're looking to install aren't a factory option you run the chance of voiding certain parts of your powertrain warranty. You might want to speak with the dealership just to be sure. That is assuming you're talking about regeaqring the 2011.

-

I'm not familiar with that kit, but if it works like i think it should just remember that you will be 'fogging for mosquitoes' so might wanna do it when there are no neighbors around to complain

. Let us know if it makes any difference for you.

. Let us know if it makes any difference for you.