Friday evening my Jeep started spewing a fair amount of antifreeze. I had noticed a problem when I stopped at the school to pick up my kids. I was talking with my brother-in-law for about 45 mins with the Jeep in drive and all of a sudden I noticed some smoke. I looked down at the temp gauge and it was over 210 but not maxed out. So I immediately shifted it to park and turned the heater on... within about a minute it had returned to about 200*. I drove it the 5 mins back to the house w/o any more overheating issues. It was a few hours later when I was able to get back out and take a look at the Jeep. I started it up and it got up to temp a LOT quicker than normal but wasn't overheating... also no heat just cold air. I saw there was antifreeze spurting out in the vicinity of the return hose from the heater core and the upper radiator hose on the thermostat housing. The engine sounding as if it was running funny but I couldn't tell for sure.

So Saturday was a bust and I wasn't able to get much work on the Jeep done. I drained the coolant, removed the upper and lower hose, flushed out the radiator, flushed out the heater core, removed the housing/thermostat, reomved the drive belt and power steering belt and then cleaned up the block some. I then went over to AZ and picked up a new water pump, thermostat, lower hose, trans cooler soft lines, and some replacement hose for the heater core hoses. Called it a day as I was needed in Baltimore.

Sunday I pulled the cowl, radiator, fan/clutch, and water pump. Cleaned it all up the best I could and then started reinstalling parts. I got the water pump installed, new thermostat, housing.... then I went to install the pulley wheel and fan/clutch and couldn't figure out how to attach them to the drive shaft flange on the water pump. I knew I wasn't missing any bolts b/c I had all of them in order since I was cleaning those too. Then I look at the old water pump and see that the flange has studs on it. Oy! Tried getting the old ones out to no avail. Going to stop by AZ today and see if it's just an odd one or if they all come like that. Pics from their online store don't show any studs on the flange....

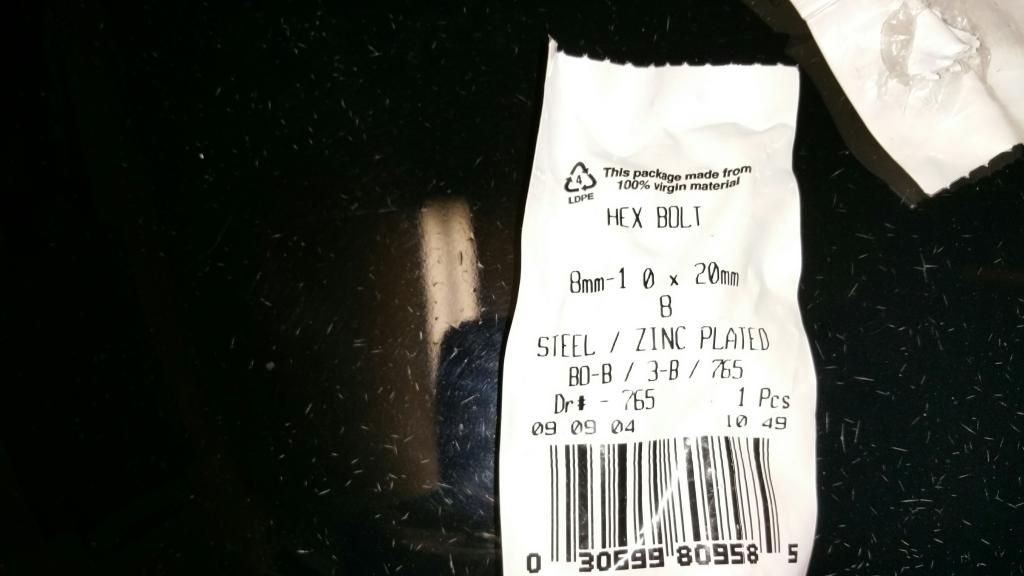

So, is it perfectly okay to find bolts that I can thread through the back of the flange to attach the fan/clutch assembly to? My only concern is that the studs might be made out of a stronger metal to absorb the force of the fan spinning than just an ordinary bolt I might find at the Home depot. Also I would assume that the studs have a reversed thread on the flange side to keep them from backing out when tightening the fan to it. Thoughts/suggestions are all welcome! TIA!

Kuntryboy's surprise YJ rebuild!!

-

-

Those studs should come out easily by double nutting them. Ask Stafford for his assistance double nutting if you need to.

-

Often times, the new water pump will come with new studs. Have them check another box to see if it has studs in it. If not usually the help section will have the replacement studs. There is likely very little room behind the fan clutch to fit an entire bolt in place with lock washers.

Like Luke said thread two nuts onto one stud and tighten them together. Then just back the stud out if you want to reuse the current studs.

-

Often times, the new water pump will come with new studs. Have them check another box to see if it has studs in it. If not usually the help section will have the replacement studs. There is likely very little room behind the fan clutch to fit an entire bolt in place with lock washers.Like Luke said thread two nuts onto one stud and tighten them together. Then just back the stud out if you want to reuse the current studs.

I helped Erock do a water pump on his a few weeks ago and it didn't come with new studs either. -

Often times, the new water pump will come with new studs. Have them check another box to see if it has studs in it. If not usually the help section will have the replacement studs. There is likely very little room behind the fan clutch to fit an entire bolt in place with lock washers.Like Luke said thread two nuts onto one stud and tighten them together. Then just back the stud out if you want to reuse the current studs.

Yes, that was a concern as well with the space between the flange and the pump body. This is why I ask questions b/c I hadn't even considered using the "double nut" method. I'll see if AZ has them in another pump's box.. I checked mine and there weren't any in the box or in the pouch w/ the instructions. I didn't look at the instructions... heh, who needs them?!

Geoff!! "Feel" like giving he a "hand"?????? Luke said you're the one to ask.............

Luke said you're the one to ask............. -

Ummmm....

-

-

So I got the studs out of the old flange and into the new one. Everything torqued, hoses on, belts on, fan/clutch on...

Then I forgot that I had found this when I pulled the radiator. Is it a major concern or can I just bolt it back in?

Edit: pic coming when Tapatalk stops being retarded

-

-

Not sure how to weld that, braise with solder?. That brass is thin, any electric weld would burn through. Might find once its all buttoned up, its holds fine. You might be able to use one of this big ass wire ties. At least make sure it doesnt rub or move at the bottom. Might have luck with auto body adhesive or similar. The main issue is the heat would break down most adhesives out there.

This might work well... JB High Heat Weld

http://www.napaonline.com/Cata…be/_/R-NCB8297_0006406686

-

Thanks Steve. I'll more than likely grab some of that JB and hit that spot with it. The radiator didn't wiggle at all when it was mounted to the grill so I don't think it's a major concern. The mounting bolts pretty much hold it in place and that downward angled end kind of adds support to it as well. Going to try and button this all up today after work. Something about driving my brother's JKU for the last few days just doesn't seem Jeepish to me. I can't seem to get a feel for her......

-

Nothing like buttoning up everything yesterday and finding the system still leaks. Oh yes there is, trying to fix it in -25 weather!

-

So whats still leaking??? From the picture you posted of the radiator it looks like it's seen better days. Not sure if the auto parts store have a pressure tester on the "tool loan" but something like this is a big help finding leaks. http://www.harborfreight.com/r…ure-tester-kit-61666.html

-

Advance stocks a coolant pressure test kit as a loaner tool.

-

It's not the lower hose spraying... looked for the crack bit ist an awkward angle and I couldn't locate it.

[youtube]uj2iYt1VTSM[/youtube]

-

I have a 2 CJ, Intakes for a 258 you can have, One is from an 86. Should be about the same.

Located in Newark.

-

Thanks again Steve!

So while I'm removing the left side of the engine, is there anything else I should take care of while it's all dismantled? I picked up a new mani/exhaust gasket yesterday. I will be drilling out the idle tubes in the carb while I have it off... have had the drill bit for a while just never got around to it. I'll clean up or replace the braided ground cable while I'm at it. Don't know what else I can do while I'm in there..... -

Thanks again Steve!

So while I'm removing the left side of the engine, is there anything else I should take care of while it's all dismantled? I picked up a new mani/exhaust gasket yesterday. I will be drilling out the idle tubes in the carb while I have it off... have had the drill bit for a while just never got around to it. I'll clean up or replace the braided ground cable while I'm at it. Don't know what else I can do while I'm in there.....NP, hope it all works out ok.. I know some of he manifold bots are a little tricky.. Use some anti-seize on them

Can't even imagine working on a jeep in this cold.. hang in there.

-

Well, yesterday I had tried to get out of work a 1/2 day early in order to put some daylight hours into the Jeep. That didn't go as planned so I got about 2 hours to work on it before it got dark out. I managed to get the vac lines tagged, disconnected them while breaking more than a few plastic connectors, disconected the electrical harness for sensors, pulled the carb, removed the sensor at the front of the intake (I think it's the original cuz man! was it in there), and then soaked the crap out of the mounting bolts with a mix of PB and Liq Wrench Penetrating oil. It was so cold out that the spray cans barely worked at all.

Not sure what I'll be able to get done after work today as I'm sure the wife won't even get out of her PJs let alone pick up the snow shovel.... -

Not much progress as I see it... I removed cleaned out the Venturis in the carb. Gave it a good but not all-together thorough cleaning and drilled out the idle tube to .037". Doesn't seem like a whole big difference from the .032 or .031 it was originally but that's what the experts say to do so who am I to argue. Gave the mounting bolts a few more blasts of PB and called it a night. Sitting in the waiting lot @ Philly waiting for my uncles plane to get in. Joy, joy!

Participate now!

Don’t have an account yet? Register yourself now and be a part of our community!