I've been trying to get my horn working and haven't seemed to be able to trace the problem. Here's what I've checked so far:

1. All fuses are in working order

2. Horn button, spring, column wire are all intact and assembled correctly

3. Horn is new (5 months) and works when hooked directly to the battery

4. I'm not getting any voltage at the horn terminals or at the column wire

5. Contact area under horn button is bare metal so no interference there

Correct me if I'm wrong but the wirirng should lay out like this...

Battery ![]() horn terminal a

horn terminal a ![]() horn terminal b

horn terminal b ![]() thru column

thru column ![]() wire attach to terminal on ring that is held off of column by horn button and spring until you depress horn button completing circuit and sounding horn

wire attach to terminal on ring that is held off of column by horn button and spring until you depress horn button completing circuit and sounding horn

I don't believe there's any relay involved or that the wrirng goes into the fuse box but I could be wrong. Just trying to exhaust all of my possibilities before I wire in a secondary button for the horn.

Horn wiring help

-

-

I've

You accidentally a few words I think. -

You accidentally a few words I think.

Yeah.... work PC was acting up a bit.

Yeah.... work PC was acting up a bit.

ok.... it was me.

-

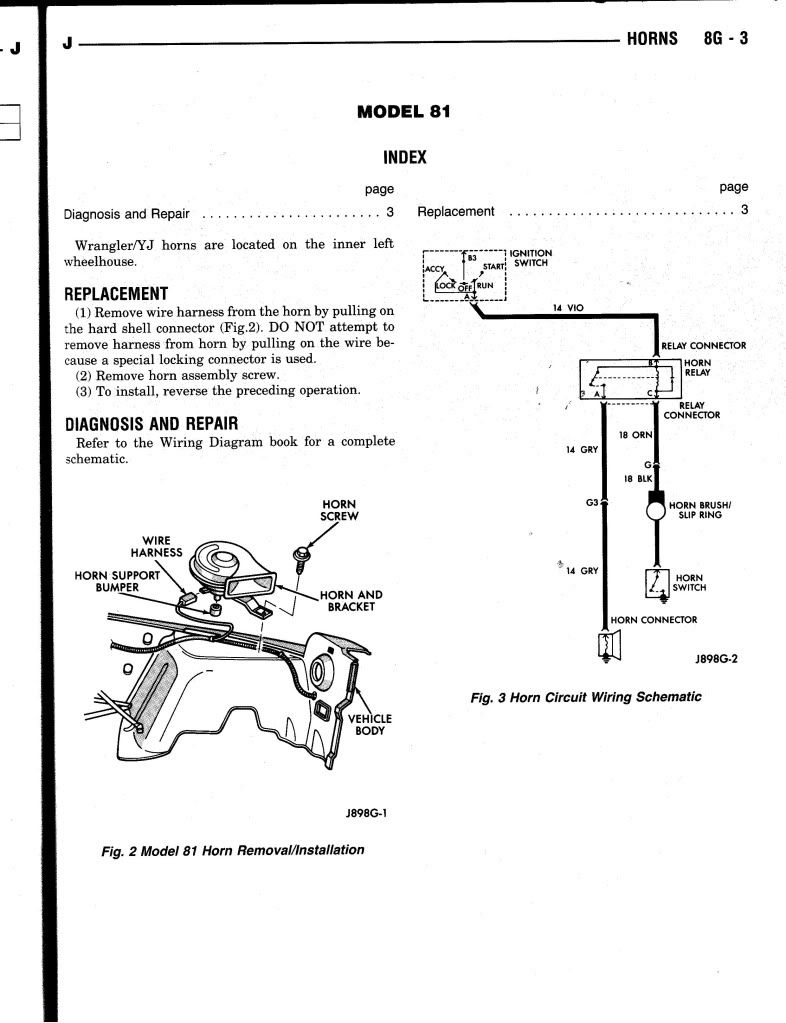

Let me look it up, but most all horns have a relay of some sort....if so you shouldn't be getting any power to the horn switch as it would actually ground the relay.

Ok just looked through the Chrysler shop manual under Jeep for 89, all of them have a relay, usually located in the power distribution center under the hood.

and...

Your wire colors might be different but that is going to be the basic circuit. -

definitely a relay in there. Be sure the horn itself is well grounded. When you confirmed you were not getting voltage to the horn did you test with a multi-meter or just go by the new horn not working?

-

So you are supplying ground to the relay when you press the horn button. That being said you should still get a voltage reading at the switch that should drop to approximate zero when the switch is depressed. If you don't have power at the switch you need to check for power at the relay terminals. It is possible tht the relay has released 'the magic smoke'.

-

Used a multimeter. Would that relay be a 3-pronged relay? There's that and also a 5-pronged relay in the wiring harness under the dash. I'm guessing that the horn where itmountsto the fender should have a little rubber bumper under it? I believe there was one when I installed it but its not there now.

-

Used a multimeter. Would that relay be a 3-pronged relay? There's that and also a 5-pronged relay in the wiring harness under the dash. I'm guessing that the horn where itmountsto the fender should have a little rubber bumper under it? I believe there was one when I installed it but its not there now.The one in the drawing is 3 terminal.

-

The horn relay is the one in the harness. The 2 relays in the fuse block are for turn signal and hazzards.

-

Thanks all. I'll dive into it today after work and see if I can get it sorted out. I'll post up my progress later this evening.

-

Welp... the relay wasn't the issue b/c the new one had no effect. I traced the line from the horn to the firewall and it has continuity. The ground at the horn is clean w/o any corrosion. I spent a few frigid moments under the dash but didn't have the patience to mess with the wiring harness (again). Guess it's time to decide if I want to run an auxillary button or try and correct the original wiring. Maybe I'll run the secondary until it warms up a bit.

I'm more than a little flustered that I am currently unable to advise other drivers what I think of their abilities to operate a motor vehicle. <Translate> It's a DOT safety issue. -

[size=2]

Welp... the relay wasn't the issue b/c the new one had no effect. I traced the line from the horn to the firewall and it has continuity. The ground at the horn is clean w/o any corrosion. I spent a few frigid moments under the dash but didn't have the patience to mess with the wiring harness (again). Guess it's time to decide if I want to run an auxillary button or try and correct the original wiring. Maybe I'll run the secondary until it warms up a bit.

I'm more than a little flustered that I am currently unable to advise other drivers what I think of their abilities to operate a motor vehicle. <Translate> It's a DOT safety issue.

[/size][size=2] I'll be wiring an "alternate" horn button in in the CJ in the next few weeks so I can pass inspection. I think my issues are in the column and I have no inclination to mess with it. If you want I can pull the CJ out of the garage and you are welcome to work on your horn where it's a little bit warmer. Just let me know.[/size]

-

I swapped columns out to fix mine. The alternate button worked but when I was putting the Jeep back together I wanted the problem fixed. I was having other steering column issues anyway.

-

Allrighty then.... well more than a few months later, I decided that I need this problem fixed. Here's what I did Saturday to try and solve the issue.

First I started by tracing the wiring with a multimeter. I started at the horn to the connector at the firewall. Good tone. Then I checked from the outer connector on the firewall to the relay. Good tone. Next was from the relay to the harness connection on the base of the steering column. Good tone. Then I checked both sides of the harness connection. Good tone. Next, checked from the harness connection to the grounding wire under the horn button. No Tone.

So now I'm positive that the issue is in the column. I decided to run an alternate horn button as I have neither the patience nor knowledge to tear apart the column and repair the wire. First, I clipped the column wire at the harness and attached a new wire to the terminal spade in the harness. Ran that to one side of the horn button. Then I ran a grounding wire off of the other side of the horn button. Checked for continuity and had good tone when I pressed the horn button. I then pushed the terminal spade into the harness and grounded the other wire to the dash frame. Push the button and no horn. Sanded the dash to bare metal and a very low horn tone but it would only sound inconsistently. I took the ground wire and tried holding it against different points and again was getting spotty tonage with the occasional full force horn sound but I couldn't keep it that way even holding down the horn button the entire time.

Question... would running a dedicated ground wire to the battery be a good idea? There's also a ground wire from my CB that I could splice into that runs directly to the battery. I just want to get some ideas before I start unfastening bolts under the dash to try and find a good ground. TIA -

I'd hook it up to the CB ground.

-

Are you sure the horn is good?

-

Reading through everything you've done it sounds like the body ground is shot. This could end up playing havoc with more than just your horn. That being said, every manufacturer has zero problems with technicians adding extra grounds, the more the merrier. My suggestion to get rid of the current problem and future ones that will show up is to run an additional ground from the battery to the firewall. If you only have small gauge wire run a couple of grounds to the firewall, say 1 from the battery and another from the engine, usually a bolt going into the cylinder head. I'm heading to Ohio this weekend, but if you still need a hand you can swing by my place the following weekend and we'll get you hooked up.

-

Are you sure the horn is good?

@ Keith- Yes sir. I can touch the positive and ground directly to the battery terminals and lose my hearing for a few seconds. I just bought the horn back in February so it's not the OEM horn though I do still have that as well.@ Mark- I know there's a ground from the battery to the block and there's another ground from the drivers side of the block to the firewall (braided copper). I will eventually upgrade to a higher output alternator and upgrading the wiring will be a must. Will replacing the grounds and alternator to positive now with a thicker gauge cable (1 or 2 AWG multi-strand) now w/o upgrading the alternator have any negative effects on the electrical system? Does there need to be a certain amount of resistance?

It seems like the easiest thing to do at the moment is tap into the negative off the CB. Decisions....

-

Will replacing the grounds and alternator to positive now with a thicker gauge cable (1 or 2 AWG multi-strand) now w/o upgrading the alternator have any negative effects on the electrical system? Does there need to be a certain amount of resistance?That will be fine.

-

Yup, like Keith said, that will be fine. It is also easy to run that ground to the firewall from the battery which i highly recomend and will most likely fix all your problems. Due to rust and corrosion you have a lot of resistance between the battery and the firewall since the ground has to flow through the rusty connections at 2 points on the engine.

Participate now!

Don’t have an account yet? Register yourself now and be a part of our community!